We have finally recovered from RV4sec and wanted to bring you a quick recap! We sold 386 tickets this year, and was on par for attendance from the previous year. It was great to see so many new faces this year and we hoped everyone had a great time.

What were thrilled to bring you:

- Awesome Keynotes by G. Mark Hardy and Jennifer Steffens!

- Remarks from Terry McAuliffe, Governor of Virginia! How could anyone forget the EPIC introduction for the Governor! =)

- Great speakers with great topics!

- Breakfast, lunch, coffee & snack breaks sponsored by Capital One and Symantec

- Amazing badges from Hack.RVA!

- RVAsec 6 pack cooler bag stuffed with swag

- Capture The Flag with live bug hunting sponsored by UNOS!

- RVAsec t-shirt with “Inside the Mind of the Hacker” logo designed by 14-year-old @AylaMadison

- Post-con reception with adult beverages (and more food) with great Passport prizes

- After party sponsored by Rapid7, GuidePoint and nVisium!

What to expect in the coming weeks:

- Surveys should be sent out shortly, please take the time to provide us your valuable feedback

- Slides will be posted

- Videos will be posted to the RVAsec YouTube channel.

- We hope to be able to post up a CTF recap as well

Thanks again to all our our speakers, sponsors and volunteers!

Next year, RVAs5c will be June 2-3, 2016.

See you next year.

Jake and Chris

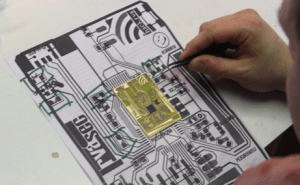

drawn, usually with special software but hobbyists sometimes just draw them by hand. The gEDA software suite has a component called “pcb” that was used to draw the badge.

drawn, usually with special software but hobbyists sometimes just draw them by hand. The gEDA software suite has a component called “pcb” that was used to draw the badge.

boards with the acid resist. Attempts last year worked but were not consistent.

boards with the acid resist. Attempts last year worked but were not consistent.

The steel blade is 1/2″ thick and the whole thing weighs 60 lbs!

The steel blade is 1/2″ thick and the whole thing weighs 60 lbs!

complicated, but it can be tedious to do, especially 350 times!

complicated, but it can be tedious to do, especially 350 times! First a solder paste containing thousands of beads of tin is drawn across a stencil that leaves the sticky grey paste where the parts will be placed. This stencil is etched copper foil. Stencils can also be plastic or steel.

First a solder paste containing thousands of beads of tin is drawn across a stencil that leaves the sticky grey paste where the parts will be placed. This stencil is etched copper foil. Stencils can also be plastic or steel. are carefully placed on the solder paste. We have had the help of over a dozen HackRVA people so far this year.

are carefully placed on the solder paste. We have had the help of over a dozen HackRVA people so far this year. The solder paste has to be melted or “re-flowed” to electrically connect the parts to the PCB. This currently is not very hi-tech: $20 donated ovens. A volunteer last year built a micro- controlled unit but the heating element died on it.

The solder paste has to be melted or “re-flowed” to electrically connect the parts to the PCB. This currently is not very hi-tech: $20 donated ovens. A volunteer last year built a micro- controlled unit but the heating element died on it. human type. We had a board last year survive a 5-hour session underneath the oven, and it worked fine–though it looked like burnt toast!

human type. We had a board last year survive a 5-hour session underneath the oven, and it worked fine–though it looked like burnt toast!

button option (red in picture) which can be soldered across the middle and far right pin on the lower center 5-pin programming header.

button option (red in picture) which can be soldered across the middle and far right pin on the lower center 5-pin programming header.